GIVE US A CALL

WATER AND WASTEWATER TREATMENT PLANTS

Star Power Tech Cont LLC. can manufacture high-quality water and wastewater treatment plants including.

MBBR Based Sewage Treatment Plant

MBBR Sewage Treatment Plant Moving Bed Biofilm Reactor MBBR Sewage Treatment Plant is an excellent solution for various waste water treatment applications such as BOD reduction nitrification and total nitrogen removal. As compared to conventional wastewater treatment systems this system is best known for improving reliability simplifying operation. Integrated with MBBR technology this treatment plant is assembled with thousands of polyethylene biofilm carriers operating in mixed motion within an aerated wastewater treatment basin

MBR Sewage Treatment Plant

Membrane Bioreactor is an innovative wastewater treatment method. As the name suggests, it combines two technologies, membrane filtration and the biological treatment. It has a number of advantages over other wastewater technologies. MBR delivers high-quality sewage, better bio treatment and have a small footmark.

Effluent Treatment Plant

Effluent Treatment is the process of removing solid, chemical, and organic substances from the wastewater produced by industries as an outcome of the production process and recycle the water for industrial use or discharge it into the environment safely. Effluent Treatment Plant has many stages in treating the wastewater produced by the factories. The influent water has acid, oil, grease, and other solid substances like plastic, paper. The Effluent water is recycled back for industry use or discharged to the environment.

PRODUCTS

Sewage Treatment Plant

Sewage treatment refers to the process of removing contaminants, micro- organisms and other types of pollutants from wastewater influent. The main objective of sewage treatment is to produce an effluent (treated waste water) and a solid waste/ sludge suitable for discharge into the natural environment.

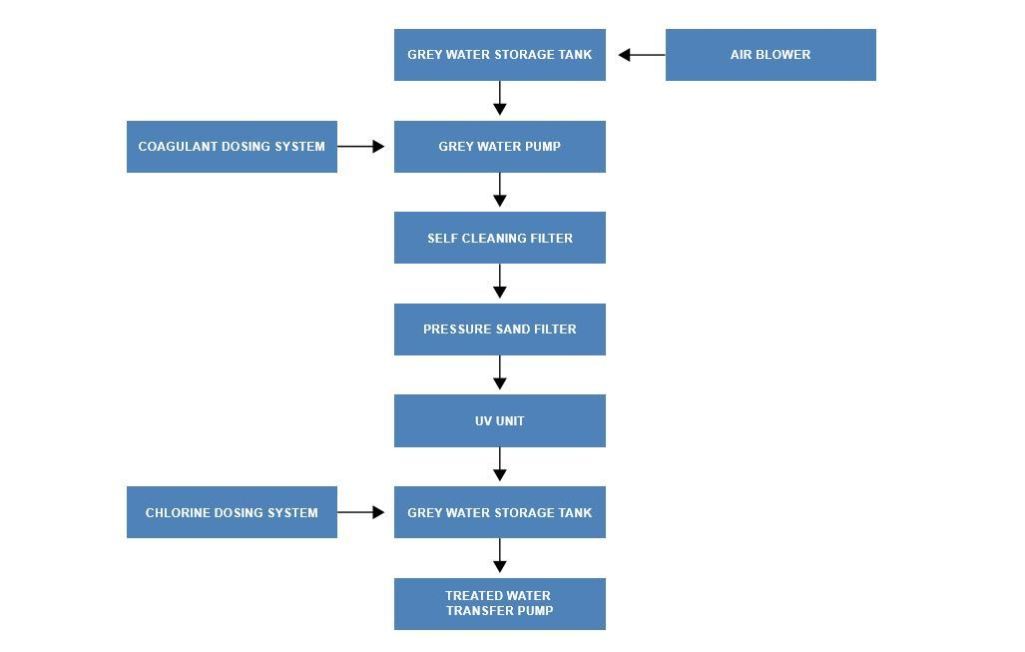

Grey Water Treatment Plant

Grey Water Treatment Plant is water from washroom sinks, showers, tubs, and clothes washers. It is not water that has come into contact with defecation, either from the can or from washing diapers. Grey water is any family unit Grey Water Treatment Plant except for wastewater from toilets, which is known as black water.

Water filtration is the process of removing or reducing the concentration of particulate matter, including suspended particles, parasites, bacteria, algae, viruses, and fungi, as well as other undesirable chemical and biological contaminants from contaminated water to produce safe and clean water for a specific purpose.

Filtration System

In Reverse osmosis system the raw water is initially passes through a pre treatment system where the suspended particles are removed and then the water is passed through a semi permeable where we apply a high pressure to remove the ions and molecules from the water to produce clear water. Reverse Osmosis system shall be used in a wide range of water sources like bore well, river water, sea water, etc.

Reverse Osmosis Plan

Degasser Unit

The function of degasser tower is to remove carbonate ions by forming carbon-di- oxide. In degasser tower stream of water is poured from top and air is blown from bottom to top. It removes the carbonic acid and other gases mixed with water by simple physical method and thereby reduce the chances of corrosion.

Lifting stations are basically used to pump wastewater or sewage from a low level to a higher level when the gradient of the area does not allow for a natural flow. There are two main elements to a lift station: the wet well and the controls. Lifting Station shall be made of concrete or GRP based on the volumetric flow.

The Star Power Fibreglass Pump Stations are specifically designed for applications where heavy-duty lightweight and corrosion resistant chambers are required. These units are supplied as a complete one-piece prefabricated unit with internal equipment pre-fitted prior to delivery. This reduces the amount of site work to final plumbing and electrical connections only.

Lifting Station

Odor control unit

Activated carbon systems are used to remove odors that are present in the foul air of sewage applications or industrial applications. The odorous compounds are absorbed to the surface of the activated carbon.

This is accomplished by passing the odorous air across a bed of activated carbon, allowing the adsorption process to occur and releasing the clean air to the atmosphere. In the outlet we have a H2S analyzer to monitor the parameters of the outlet flow. Our odor control system will be skid mounted and it is very easy to install and operate.

Ultrafiltration System

Ultrafiltration is a membrane filtration process similar to Reverse Osmosis, using hydrostatic pressure to force water through a semi-permeable membrane. Ultrafiltration is a pressure-driven barrier to suspended solids, bacteria, viruses, endotoxins and other pathogens to produce water with very high purity and low silt density.

© 2024 starpower.ae

Falah Star Group is an international, multi-disciplinary company of G.C.C., with operations in the Middle East and beyond. Our vast experience garnered over the last 43 years offers clients comprehensive engineering solutions for steel fabrication, contracting, water treatment etc..

GIVE US A CALL

DROP A LINE

Sharjah, United Arab Emirates ,

P.O Box : 69487

LOCATE US